A SHELF WORTH MILLIONS

STILL THEY ARE EMPTY

There is no need for costly capacity expansion or campaigns to ensure that customers always find what they're looking for — and shelf stackers always know in real time which shelf or cooler to fill.REAL-TIME TURNOVER MONITORING

FULL SHELVES, ALWAYS ACCURATE DATA

Shelves dispensers are already available in many stores - which is a practical solution, because if the goods are pushed less, they push it to the shelf line, making it more likely to make a purchase.

The dispenser also makes the shelf image uniform, the last pieces never stand inside the shelf, no need to look for them.

The only major disadvantage of simple mechanical solutions, however, is that they are not joined by online loss technology. Thus, the shelf stocking staff will be able to monitor the reduction of stocks only by visual inspection.

This is not only a difficult process, but also a very time-consuming process, which can occupy a large proportion of the working time, and therefore the replenishment staff of most commercial units only perform active observer work if they have the capacity to do so.

Unfortunately, stores rarely know exactly

when goods run out of a shelf or refrigerator, or where and when to prepare for refilling.

A quarter of the shelves thus almost always stands empty, because it is impossible to track the running out of products by traditional methods in real time.

This business dilemma is solved by the big data based consumption monitoring goods dispenser, with which the shelves can always be filled, so there will be tens of millions of revenue missing.

And for this continuous follow-up, you don't need any extra manpower.

UPGRADE YOUR DISPENSERS!

MasterShelf consumption monitoring system

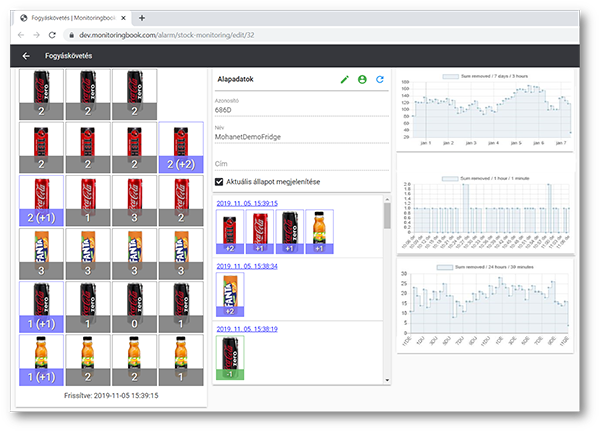

The MasterShelf onsumption monitoring system monitors shelf status 24 hours a day, 7 days a week, and sends real-time status reports to the computer of the personnel charged with loading the goods — or even to the smartphone.

The system electronically logs the consumption data collected from the counters of dispensers suitable for products of any size. Using a large sample data analysis, it makes analysis and forecasts for sales, trade, brand marketing and operation.

Transparency ensures better organisation of work, improved competitiveness and a sharp rise in return — with decreasing cost levels.

Why isn't there a smart consumption monitoring dispenser everywhere in the stores?

Simply because, although the principle is not new, the technology is..

MasterShelf is a unique development and is unique in the Hungarian market.

The system triggers the observer work that takes at least 1 hour per day from the 8 hour working time of the shelf stacking staff - which can be spent on replenishing products.

Get accurate, real-time data about:

- Where and how quickly the products run out

- According to what trend the product is running out.

- Exactly where you run out better, where to recharge, which are the

THE GOOGLE ANALYTICS OF THE FMCG MARKET

This is how the consumption monitoring system works in practice:

An own developed running out-tracking sensor and a data communication device are connected to the spring-loaded dispensers.

The data from the smart dispensers placed on the shelves is received by a virtual server, which stores, processes and transmits it to various graphical display software. They automatically indicate, then analyze and visualize the information in real time so that anyone from the sales manager to the uploader can read it immediately.

The sliding elements and product separators with the counter sensor are fixed perpendicularly to the dividing rails (T-rail) located parallel to the shelf. The sensor is included in the plastic rail of the pusher element to protect it from environmental influences. Spring loaded pusher have a stop for fast and efficient dispensing of goods. This type of product goods dispenser is the most widespread on the market due to its affordable price. Its popularity is due to the fact that it can be easily matched to most products, as the dividing elements fixed on the divider rails can be freely moved sideways, thus adjusting to the width of the goods.

With smart dispensers, you can track the running out of any product, and the Consumption monitoring sensor can be integrated cost-effectively into existing dispensers.

The onsumption monitoring sensors on the shelves are connected to an IoT communication device that transmits data to the cloud in a fraction of a second. Here the server of the monitoring system receives, evaluates and analyzes the data.

The software belonging to the server not only sends alerts and generates statistical data streams, but also can visually display the same information in seconds. This way you can always know exactly how your products are running out on which shelves.

This is what happens when you introduce smart shelves:

In contrast to conventional dispensers, if the quantity of goods is dangerously reduced in any dispenser, the system immediately sends a signal automatically, saving time.

And beyond that...

- On a data basis, it also proposes to create the ideal shelf image: instead of human observation, manual data analysis, it automatically examines trends and thus helps make every shelf more profitable.

- It shows the real business potential of a particular unit, shelf and placement: only instead of cash register data or intuition, it provides a solid basis for any business decision.

- It shows in real time where we can raise prices, which product should be relocated, where extra promotion should be and where superfluous — thus optimizing costs.

What else can the MasterShelf CONSUMPTION MONITORING SYSTEM do?

Monitors product consumption and replenishment (or even lack of replenishment) of the dispensers in real time. You can even see a product lifted and then being put back on the shelf.

In case of fridges,, monitors how many times a refrigerator door has been opened in a day, and the system immediately alerts you if the doors remain open or closed permanently. (This is how it helps to avoid human mistakes.)

If the light is not on or when the machine is switched on and off, the system also indicates. (If a refrigerator fails, you can repair it faster.)

monitors the power supply, internal temperature and also measures energy consumption, which is important for the service center.

Do you want real-time information about your shelves and refrigerators? Get a customized offer for your business, which can be easily built anywhere!

THIS IS HOW REAL TIME CONSUMPTION MONITORING

WILL BE AN INDISPENSABLE ROUTINE

While a simple mechanical dispenser provides only comfort, real-time onsumption monitoring makes everyday work tangibly easier, more transparent and efficient.

There is no need for an employee to walk around the store and monitor the customers or missing products, no overtime due to late spotted empty shelves and, of course, no more empty shelves.

However, the big data based analysis carried out by the software will be an indispensable help in achieving the strategic goals of the company.

Imagine accurate measuring of the results of local, regional or national promotions and marketing campaigns.

It's like tying Google Analytics into your shelves.

Imagine that for the first time before concluding annual agreements, you can base your decision on real statistical data — negotiating so that you know exactly how much your partner's trading unit actually sold.

Imagine the positional advantage of creating a new strategy, a new planogram or even just individual facings compared to competitors who do not have accurate weight tracking data per piece and second.

We are engineers - but also businessmen who know that this information is of invaluable value in competent hands.

We're ready to make your shelves and refrigerators smarter and your company more competitive.

TRY FREE FOR 10 DAYS BEFORE DECIDING...

Experience how the system works in a 10 day free trial.

What we provide is:

- We give you a demo suitcase in which you can test the smart consumption monitoring of your own products.

- We also provide a phone and app for onsumption monitoring.

- We provide technical assistance for setting parameters for different products in the app.

- A payback calculator to calculate in how many months the consumption monitoring system will recover.

This allows you to see firsthand what MasterShelf can do before you request an RFQ.

STEP BY STEP:

FROM REQUEST FOR QUOTATION TO INSTALLATION

Mechanics, electronics and information technology that make up the MasterShelf onsumption monitoring system are always based on the same logic.

However, we know that there are no two identical refrigerators or shelving systems, so we always adapt the production process to the needs of the customer and to the conditions of the refrigerator/shelf.

This is how you will have a smart onsumption monitoring system in 5 steps:

PERSONAL MEETING

After completing the contact form, we will agree on the date of your personal or online meeting within 1 week. Here we show the operation of the system, discuss the challenges, explore the hidden problems and find a solution to them.

Here we present a dispenser equipped with a smart consumption monitoring system, so that you can see the potential of the technology with your own eyes and answer questions.

UNIQUE REQUEST - UNIQUE OFFER

If you are convinced by the system and have decided which is the shelving system or refrigerator that you want to be the first to track traffic in real time, then all you have to do is give us the dimensions of the shelf and its location in the store or deliver a test refrigerator to us.

Our engineers document the individual dimensions of mechanical and electronic devices and determine their installation time.

This is necessary because all shelving systems and refrigerators have unique specifications (number of shelves, depth, height, length, etc.) and require a unique production process. Therefore, we also always prepare the budget for the project individually.

The individual quote will be compiled within 2 weeks of delivery of the sample.

Manufacture of specimens

After the issuance of the price offer, we will conclude a contract for a pilot project, during which a minimum of 50 smart goods dispensing shelves and 5 samples will be produced from the refrigerator.

Mechanical and electronic elements are modeled and manufactured according to the parameters of the sample cooler or shelving system. (This is why it is important that our engineers explore the unique features of the shelving system or cooler before signing the contract.)

During this phase, our engineers still produce all parts manually and one by one, and later production lines and robots do the same.

The production of smart consumption monitoring systems or sample coolers takes approximately 2 months.

TESTING THE SYSTEM

The specimens are assigned a unique code number during assembly. After that, the smart dispensers are installed with the onsumption monitoring software, which can be tested live for 3 months.

A shelving system or cooler type has a code number which is relevant if, after a successful test, they give the green light to mass production.

SERIAL PRODUCTION

If the test was successful and satisfied with the final result, they can submit their serial production requirements based on the code number obtained.

It is important that a shelving system or a refrigerator has a code number, and since the design and manufacturing are 100% unique, we must start a new pilot project for each new model.

This reduces the risk significantly: they do not have to commit to a large-scale investment in advance, and in each case we create a unique and reliable system, which is already proven in the test plant.

WHEN WILL MY SHELVES BE SMART?

Depending on the number of pieces, about 3-4 months. Of this, it takes 9-11 weeks to manufacture and install, another 6 weeks to sea freight, as part of the production is carried out overseas.

This means that it will take about 8 months from contacting if you want to install the MasterShelf sconsumption monitoring system on all shelves and refrigerators.

CAN BE INSTALLED IN ANY SPRING DISPENSER SHELF AND REFRIGERATOR

- Beer, wine, soft drinks

- Sweets

- Soup and pudding powders, spices

- Cheese and meat products packaged in vacuum

- Tobacco products

- Cosmetics, perfumery

And practically any other product that you would put in the shopping space in store shelves.

You outline the challenge, and we deliver you the engineering solution that clears the empty shelves, ensuring an annual revenue increase of up to millions. All this without costly capacity expansion, without campaigns - fully automated.

REQUEST A PERSONAL OFFER

Follow product consumption in real time and increase annual traffic without costly capacity expansion and risky marketing campaigns.